Kinetic Energy Recovery System (KERS) is the word which is being associated with Formula 1 cars and has been in the Headlines for quite a while. All 2010 Formula 1 cars feature KERS as an integral part after it was made mandatory by FIA to be installed and is currently being manufactured by Flybrid Systems.

What is KERS?

KERS as the name suggests is an energy recovery system also known as regenerative system but importantly the KERS is quite advanced than the conventional energy recovery systems. The mechanism functions in a way that it reduces the speed of the vehicle by converting some of its kinetic energy and/or potential energy( in case of elevations) and storing it into a useful form of energy instead of dissipating it as heat as seen in conventional dynamic braking system.

Technically KERS can be defined as an Electric generation, storage, and propulsion system generating electricity during slow down or braking, storing it in batteries, and later assisting the gasoline engine by boosting acceleration with the help of electric drive motors.

The device will be installed in F1 cars to save energy utilized while braking, store it and further use it when required. KERS is of two types one mechanical and the other electrical.

What does KERS contains?

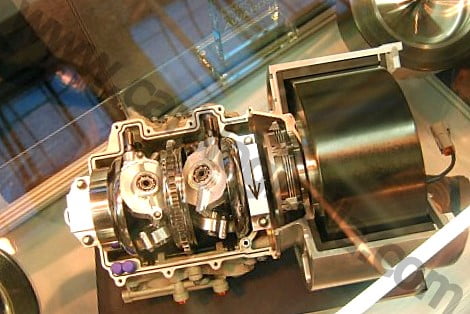

The system basically consists of a CVT( Continuously Variable Transmission ) unit , a clutch, an epicyclic gearbox and a flywheel

(The mechanical type contains a FLYWHEEL to retain power while the Electrical type contains an electric motor twinned with a BATTERY or CAPACITOR or FLYWHEEL)

Working of Kinetic Energy Recovery System

The engine drives the KERS system and it is coupled with the drivetrain. The drive comes into the CVT unit which effectively changes the gear ratio in accordance with the flywheel and rotates the flywheel. The control pistons seamlessly change the gear ratios between the input and the flywheel moving at a much faster rate than the actual drive(5:1 ratio at 64,000 rpm). The amount of energy stored or released depends upon the torque transfer taking place within the CVT unit, which is controlled by the position of the levers.

F1 KERS Specifications

The energy efficiency of the KERS is nearly 60% as compared to conventional petrol-electric hybrid with 37% efficiency. The structure is made up of carbon fibre which is extraordinarily strong and can take up pressures upto 1,150 bars.

The system is capable of generating 100kw but is limited to 60kw(80.5 BHP) by FIA regulations and weighs 25kg in whole including all the components along with the working fluid. The 60 kw power generated is much more than the 23kw provided by same systems installed in Prius.